Simple RPM-Meter

Recently Great Scott built his DIY version of a tachometer which I thought was very cool. But using an ATmega for this job, I found a bit overpowered. So I tried to force all tasks (measurement, calculation, I²C protocol and OLED display) into the huge 1KByte memory of an ATtiny13A.

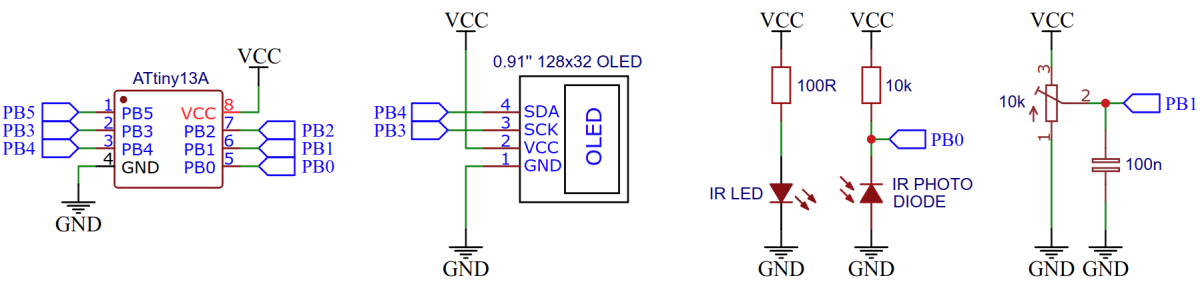

Since the ATtiny13 does almost all of the tasks, the wiring is pretty simple:

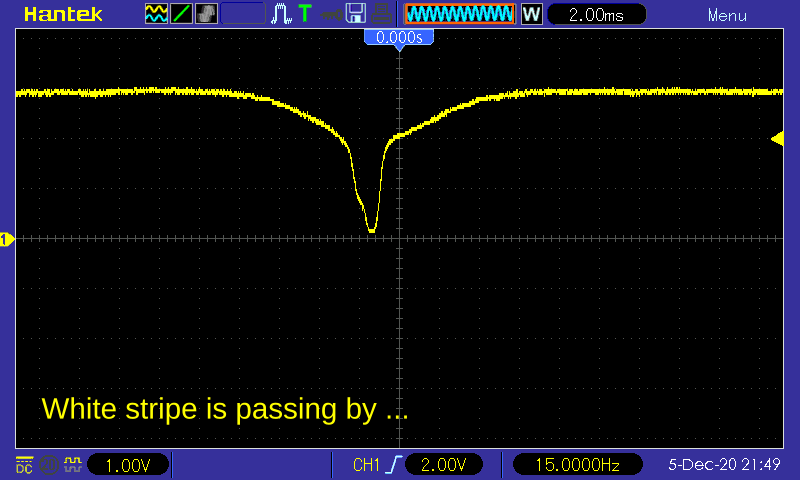

The IR LED emits light, which is reflected by the rotating object and detected by the IR photo diode. The photo diode changes its conductivity depending on the strength of the reflected light. If the rotating object has exactly one white stripe on an otherwise black surface, then the photo diode changes its electrical resistance twice per revolution and the voltage between the diode and the 10k resistor rises once above and falls once below a certain threshold, which is defined by the variable resistor.

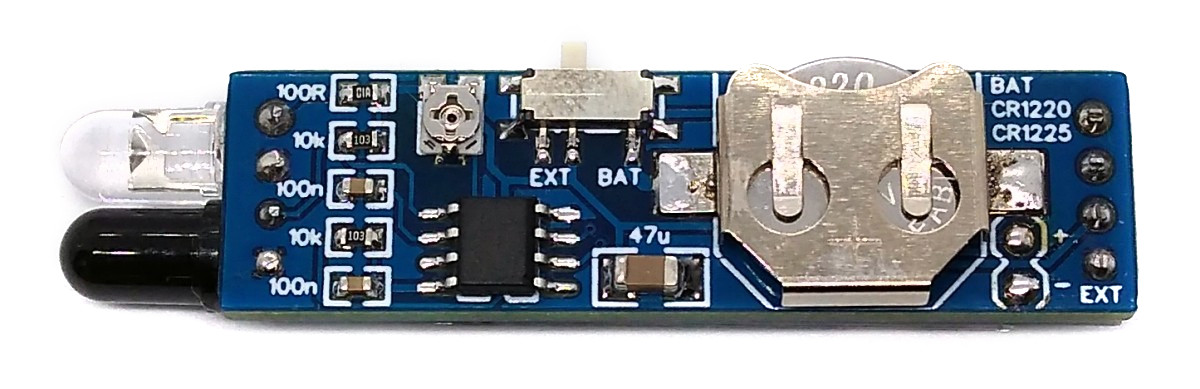

If you want to use a coin cell to power the device, please remember that only the rechargeable LIR1220 Li-Ion batteries work. The “normal” CR1220s don’t deliver enough power.

The IR photo diode is connected to the positive input of ATtiny’s internal analog comparator, the variable resistor for calibration is connected to the negative input. An interrupt is triggered on every falling edge of the comparator output which saves the current value of timer0 and restarts the timer. The 8-bit timer is expanded to a 16-bit one by using the timer overflow interrupt. The saved timer value contains the timer counts per revolution. The RPM is calculated by utilizing the following equation:

RPM = 60 * F_CPU / prescaler / counter= 60 * 1200000 / 64 / counter= 1125000 / counter

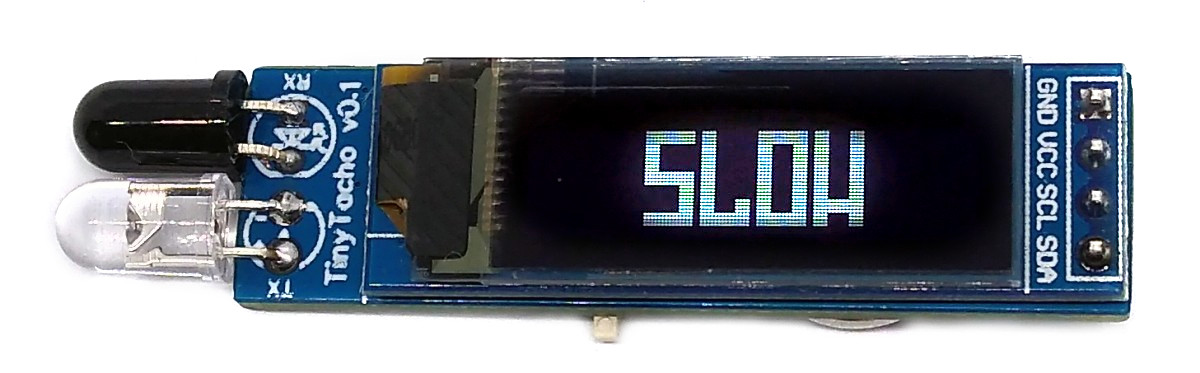

The calculated RPM value is displayed on an I²C OLED display. The I²C protocol implementation is based on a crude bitbanging method. It was specifically designed for the limited resources of ATtiny10 and ATtiny13, but should work with some other AVRs as well. The functions for the OLED are adapted to the SSD1306 128x32 OLED module, but they can easily be modified to be used for other modules. In order to save resources, only the basic functionalities which are needed for this application are implemented. For a detailed information on the working principle of the I²C OLED implementation visit TinyOLEDdemo.

// global variablesvolatile uint8_t counter_enable = 1; // enable update of counter resultvolatile uint8_t counter_highbyte = 0; // high byte of 16-bit countervolatile uint16_t counter_result = 0; // counter result (timer counts per revolution)// main functionint main(void) {uint16_t counter_value; // timer counts per revolutionuint16_t rpm; // revolutions per minutePRR = (1<<PRADC); // shut down ADC to save powerDIDR0 = (1<<AIN1D) | (1<<AIN0D); // disable digital input buffer on AC pinsACSR = (1<<ACIE) | (1<<ACIS1); // enable analog comparator interrupt on falling edgeTIMSK0 = (1<<TOIE0); // enable timer overflow interruptsei(); // enable all interruptsOLED_init(); // initialize the OLED// main loopwhile(1) { // loop until forevercounter_enable = 0; // lock counter resultcounter_value = counter_result; // get counter resultcounter_enable = 1; // unlock counter resultif (counter_value > 17) { // if counter value is valid:rpm = (uint32_t)1125000 / counter_value; // calculate RPM valueOLED_printW(rpm); // print RPM value on the OLED} else OLED_printB(slow); // else print "SLOW" on the OLED}}// analog comparator interrupt service routineISR(ANA_COMP_vect) {if(counter_enable) counter_result = (uint16_t)(counter_highbyte << 8) | TCNT0; // save result if enabledTCNT0 = 0; // reset countercounter_highbyte = 0; // reset highbyteTCCR0B = (1<<CS01) | (1<<CS00); // start timer with prescaler 64 (in case it was stopped)}// timer overflow interrupt service routineISR(TIM0_OVF_vect) {counter_highbyte++; // increase highbyte (virtual 16-bit counter)if(!counter_highbyte) { // if 16-bit counter overflowsTCCR0B = 0; // stop the timerif(counter_enable) counter_result = 0;// result is invalid}}

Since there is no ICSP header on the board, you have to program the ATtiny either before soldering using an SOP adapter, or after soldering using an EEPROM clip. The AVR Programmer Adapter can help with this.

avrdude -c usbasp -p t13 -U lfuse0x2a:m -U hfuse

0xff:m -U flash

tinytacho.hex

PROGRMR=usbasp make install to compile, burn the fuses and upload the firmware (change PROGRMR accordingly).The measuring range depends on:

This results in a measuring range from 17 to 62500 RPM.

To increase the measuring range, on the one hand the clock frequency of the timer must be increased by decreasing the prescaler and/or increasing the CPU clock frequency, on the other hand the counter and result variables must be expanded to 32 bits. Furthermore, the OLED_printW routine must be adapted so that 32 bit values can be displayed on the OLED.

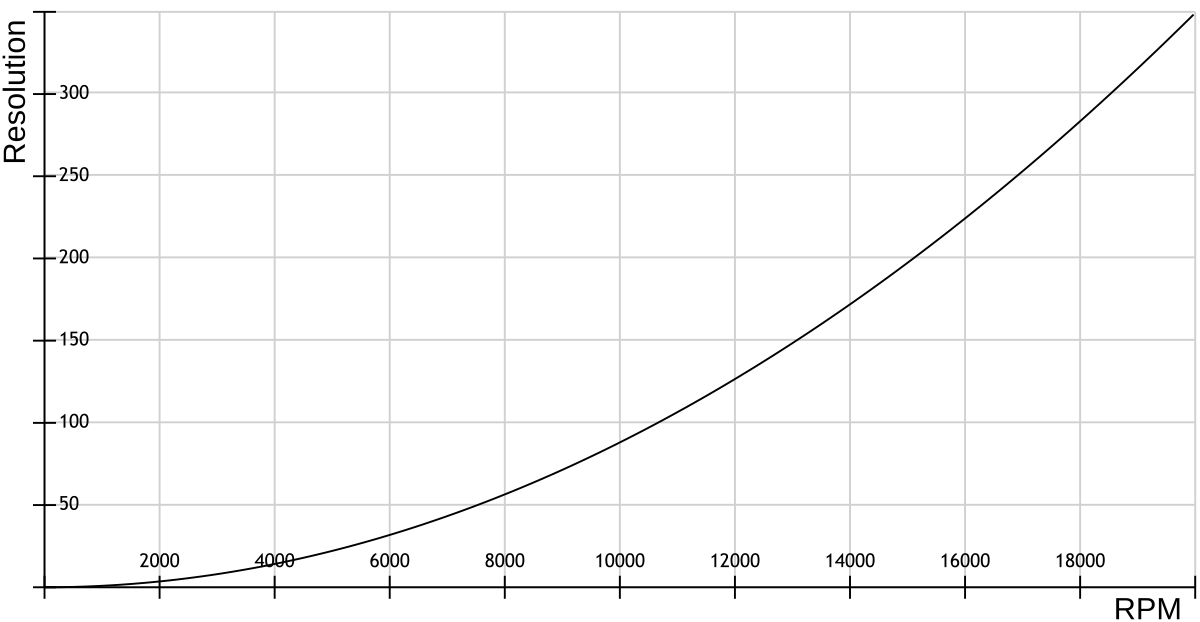

The measuring resolution depends on the resolution of the timer/counter, which is in fact its clock frequency. Due to the calculation formula, the RPM value is not proportional to the value of the counter, it is rather hyperbolic. This also means that the measurement resolution is not constant over the entire measurement range. With the set clock frequency of the timer/counter of 18.75 kHz, the following resolution results depending on the measured RPM:

The resolution in the diagram shown means the minimum distance between two measured values (the higher the value, the worse the resolution). To improve the resolution, the clock frequency of the timer/counter must be increased (see above). In order not to reduce the measuring range as a result, the counter and result variables must be extended to 32 bits.

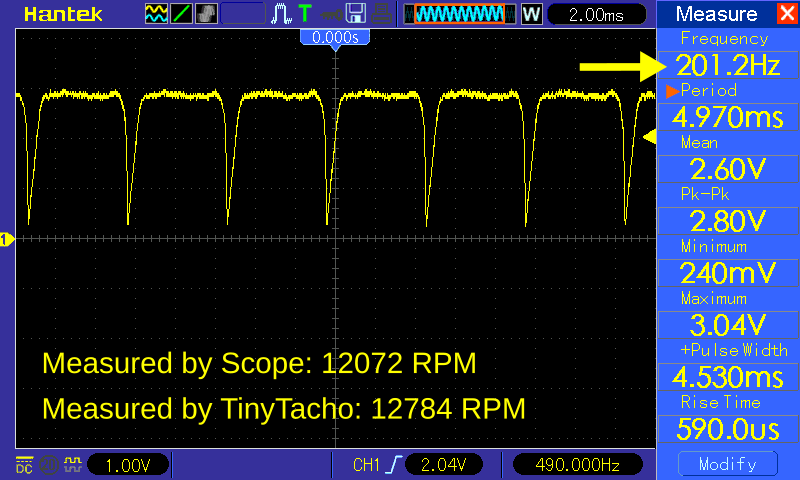

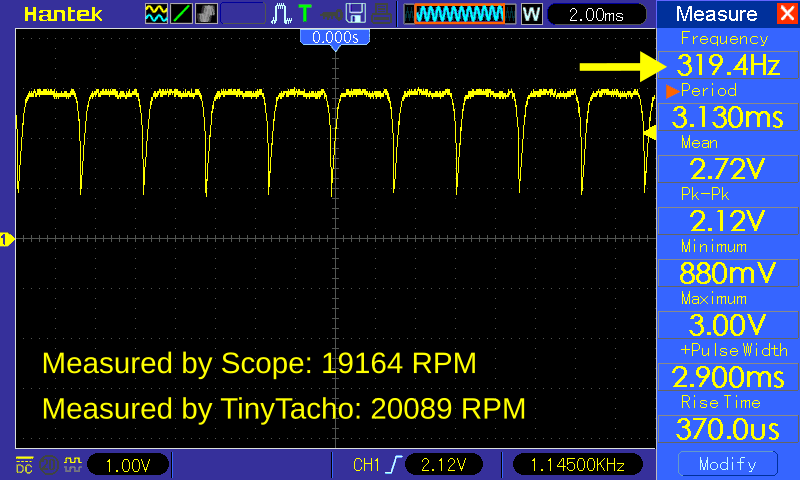

The measurement accuracy essentially depends on the accuracy of ATtiny’s internal RC oscillator. According to the data sheet, this is +/-10% with the factory calibration. This can be improved to +/-2% by manual calibration. For even better values, a precise external clock signal would have to be used, but this exceeds the purpose of this project. With high RPM values, the latency of the interrupt service routine must also be considered.

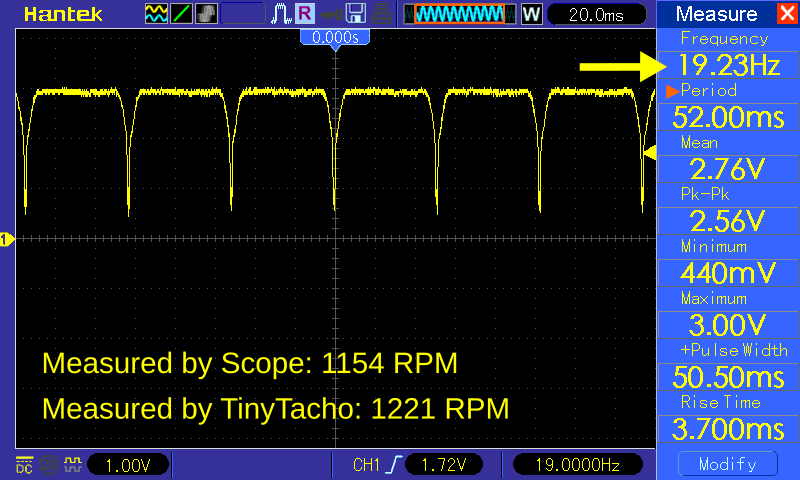

A simple plausibility check can be carried out with the video method at lower speeds. More details can be found in Great Scott’s video. In addition, the measured values can be compared with the manufacturer’s specifications for the motor on which the RPM was measured. The TinyTacho passed both tests.

The voltage behavior at the cathode of the photodiode can be measured with an oscilloscope. First of all, it can be assessed here whether there is a uniform, clean and glitch-free wave, and thus whether a reasonable detection of the white stripe passing by is possible at all. The frequency of the wave measured on the oscilloscope then automatically indicates the number of revolutions per second. If you multiply this value by 60 you get the RPM and can compare this with the value displayed on the OLED. In all measurements, this value was within the theoretically predicted accuracy (the oscillator of the ATtiny was not manually calibrated).

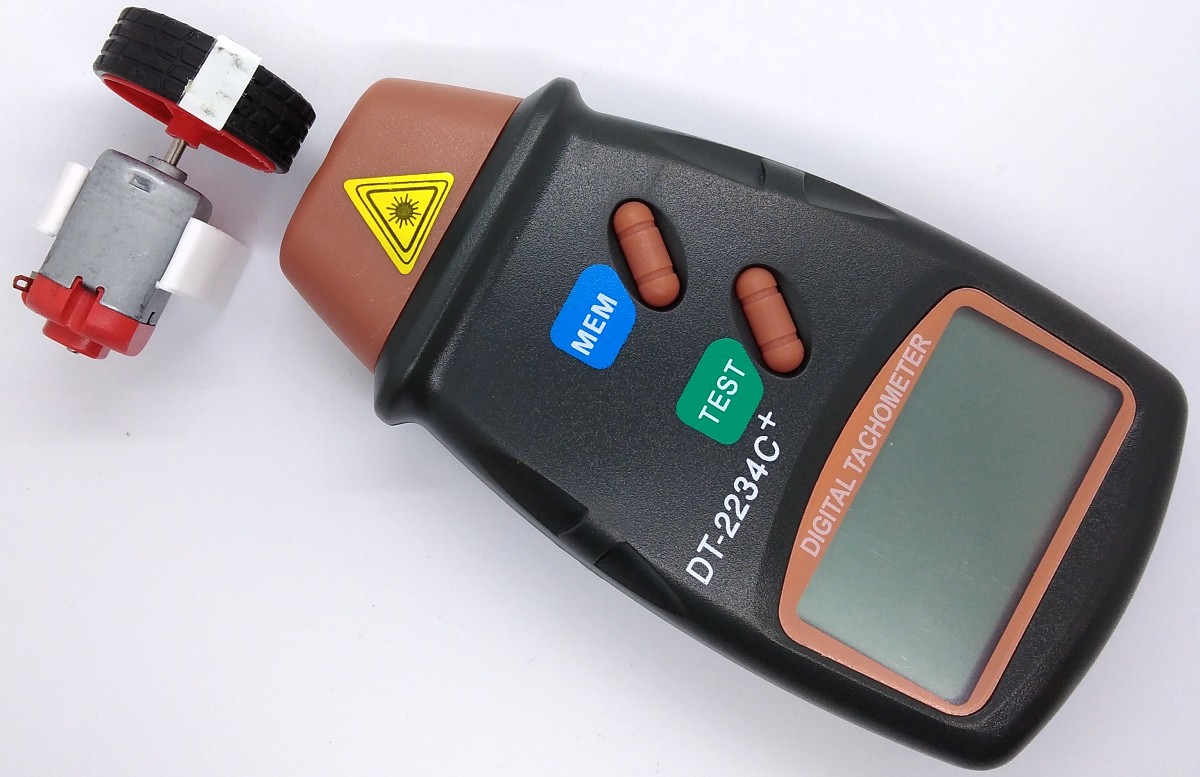

The comparison with the measured values of the cheap commercial tachometer DT-2234C+ showed the same results as with the oscilloscope.

Even if TinyTacho was intended more as an educational and fun project, it delivers plausible readings, especially with a calibrated oscillator. In contrast to the commercial products, it is much smaller and significantly cheaper. If you can do without very accurate measured values with high resolution, then the TinyTacho is a useful measuring instrument.

This work is licensed under Creative Commons Attribution-ShareAlike 3.0 Unported License.

(http://creativecommons.org/licenses/by-sa/3.0/)